|

How to fix a ZX9R Gearbox |

|

|

Symptoms:

When 3rd gear was engaged and power applied, it would slip in and out of gear with a sudden jerk. When changing up and holding selector it would still do it, however changing down and holding selector would stop it.

So what's the cause?

A bit of searching around some of the ZX9R forums shows that the C1 (98/99) ZX9R was prone to this exact problem. Basically the 3rd gear engages with the dogs on the 5th gear on the output shaft by only a few millimetres. As the circlips and washers wear, you get some movement, enough to allow the dogs to disengage. Combine this with some missed shifts and the dogs get worn enough that they start to slip and from there the problem only gets worse.

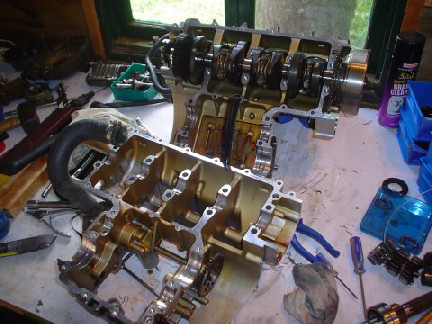

So the engine had to come out and the crankcase had to be split. I won't go into the details of how to do this, the best thing to do is to get a hold of a Haynes manual which will describe every step and how to do it. They are a bit spread out though so I wrote out all the steps on a bit of paper so I didnít miss anything, then referred to the manual for specifics. Here are some photos of the process.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

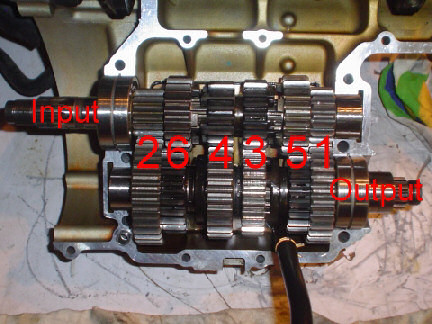

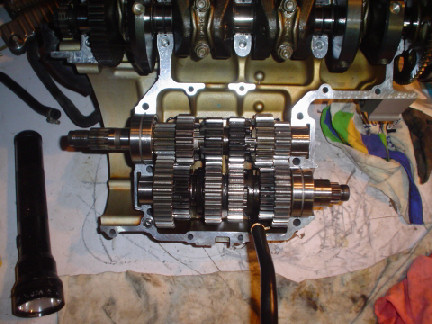

On splitting crankcase I saw this:

-Missing Positive Neutral Finder ball. These are located in slots in the selector fork groove on the 5th gear. There are normally three, one of mine was missing.

-Dogs on 3rd gear on input shaft appeared to be worn. I also found the end of a broken circlip in the sump.

|

|

|

|

|

|

|

|

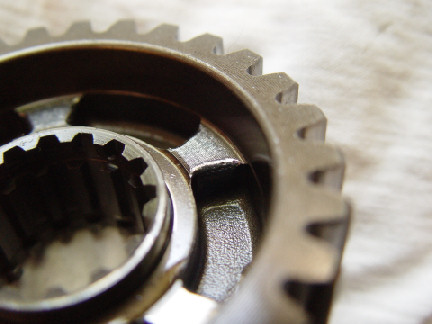

-Pulling the two shafts out made it easier to see that the dogs on the output shaft 5th gear that engage with the inside of the 3rd gear were worn, as were spokes of the 3rd gear that they engage with.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-The selector fork that moves the 5th gear on the output shaft had wear marks on it too.

|

|

|

|

|

|

|

|

-The broken circlip came from the other end of the output shaft and held 2nd gear in place.

I had two options at this stage:

-I can source new parts to replace the ones that need replacing, which worked out at around $750.

-I can source a second hand box for $550, plus around $80 in clips and seals etc.

I decided to go the second had box route, however the first one I was sent looked a bit average. The second one the wrecker sent turned out to be a lucky break, although it was labelled as being a C series box, it was actually from an E series bike. This had itís good and bad points. On the upside the gear dogs are better designed in that they are rounded and undercut, and they were in much better nick than my old ones.

|

|

|

|

|

|

|

|

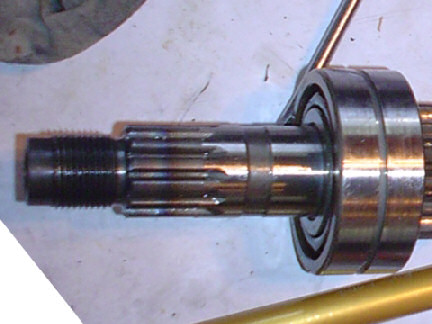

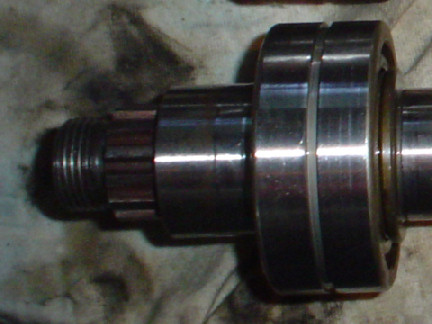

On the downside the two shafts are not a straight swap. The E series input shaft is longer at the clutch end, which would require a new clutch lifter.

|

|

|

|

|

|

|

|

|

|

|

The output shaft is approx. 3mm longer at the front sprocket end, which would offset the front sprocket, so I would have to offset the rear sprocket to match. I would also have to get a new front sprocket cover, or find a way of sitting it 3mm further out. I also couldnít actually find anyone who had done this conversion, so I had no idea whether it would work or not.

|

|

|

|

|

|

|

|

|

|

|

|

This left me with the option of moving all the cogs across to my input and output shaft, along with a new set of circlips. This seemed like a good idea, but there were a few obstacles. Like the splined washers they put between the 3rd and 4th on the newer box that lock together are designed to be offset so the larger one can lock into a groove on the output shaft, which the earlier model shaft didn't have. Taking the locking bits off one of the washers with the bench grinder fixed that one, and it all fitted in nicely.

The only other hassle was the input shaft has an extra circlip and washer on it and a different cog for 2nd to suit, so I had to keep my original, which is in good nick anyway.

|

|

|

|

|

|

|

|

I also noticed that the selector drum has a slightly different profile to the grooves where it pulls some of the gears out before putting them back in again, so I went with the newer one for that as well.

|

|

|

|

|

|

|

|

Everything is back together and running fine. The gearbox feels more "positive" when changing gears, and now the positive neutral finder has all three steel balls in it (one was missing on the old one) it works much better too.

Another bonus was that I smoothed out the little grooves that had been worn into the splines of the clutch basket etc. so the clutch is working much better now too.

More info on another way of fixing the same problem, but one that requires some machining etc, can be found at http://www.kgrant.co.uk/Forum/phpBB2/viewtopic.php?t=324

|

|